Thanks to their longevity, durability, and reliability, lead-acid batteries are a preferred choice for motive power applications. Providing reliable power to electric forklift trucks for material handling, airport tuggers, and even resurfacing the ice at hockey rinks, lead-acid batteries are probably at work in more applications than realized!

Having provided lead-acid forklift batteries to the American market for the past 70 years, Battery Builders, LLC wants key markets to understand how lead-acid batteries can benefit their specific applications. So, let’s get into it!

What are Lead-Acid Batteries?

Lead-acid batteries are rechargeable batteries that use lead and sulfuric acid to charge and discharge electrical energy.

When lead is submerged in sulfuric acid, it creates a controlled chemical reaction. The reaction then causes the battery to generate electricity. This reaction can then be reversed to recharge the battery later on.

The main materials needed to build a lead-acid battery include:

Lead peroxide (PbO2): the dark brown, hard, and brittle substance that forms the positively charged plate.

Sponge lead (Pb): pure lead in a soft sponge condition that acts as the negatively charged plate.

Dilute sulfuric acid (H2SO4): with a 3:1 ratio of acid to water, a majority of the heat released in dilution comes from the hydration of the hydrogen ions. It is highly ionized, a strong acid, and a good electrolyte.

Put these elements together and you get a highly powerful battery that has been tried, tested, and improved since its inception in 1859.

Benefits of Lead-Acid Batteries

- Cost: lead-acid batteries provide major cost efficiencies compared to lithium-based counterparts.

- Reliability: made from a proven and well-understood technology. When crafted conscientiously, lead-acid batteries are extremely durable and provide long-lasting service.

- Low Self-Discharge: lead-acid batteries have one of the lowest rates of self-discharge among rechargeable battery systems at about 40% per year.

- High Discharge Rates: lead-acid batteries have the capacity for high discharge rates.

What Industries Rely on Lead-Acid Batteries?

Although lead-acid batteries have been around since the 1800s, they are still popularly used in their improved form today across a range of fields. Just a few of these industries include:

Forklifts

Battery-run forklifts and Zambonis have almost entirely replaced those powered by natural gas. Besides cheaper operating costs, electrically-powered forklifts and Zambonis eliminate the danger of noxious exhaust fumes or carbon monoxide buildup in an enclosed space.

The heavy weight of lead-acid batteries is actually a benefit for stable forklift operation. Lead-acid batteries placed toward the back of the forklift act as a great counterbalance to the load being handled at the front.

As long as forklifts remain an essential aspect of the manufacturing and material handling industry, lead-acid batteries will continue to be in demand.

Aircraft Tugs

Aircraft towing equipment is critical to maneuvering planes on the ground into tight spaces or within busy transit corridors. Lead-acid batteries provide aircraft tugs a reliable source of power to meet their demanding application.

Zambonis

Zambonis are ice resurfacing machines used at skating rinks to maintain ice quality. Lead-acid batteries are a natural fit for this application, delivering consistent power when the Zamboni is needed.

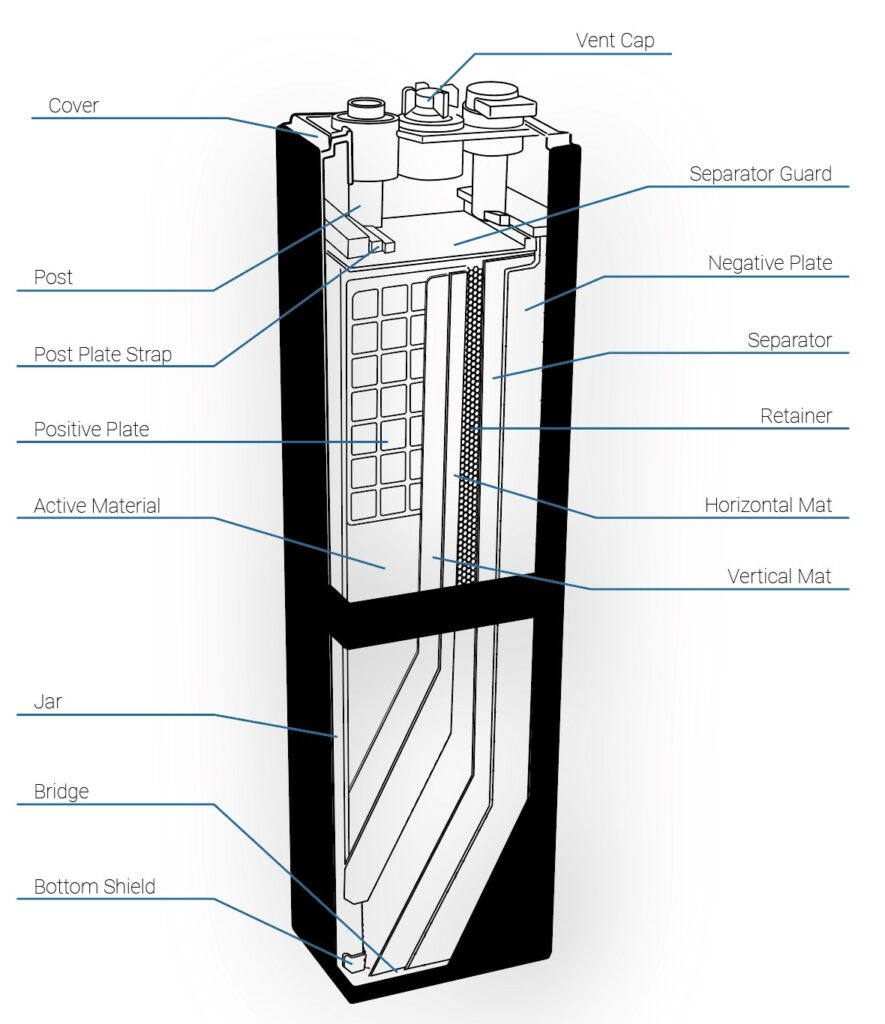

Inside View of a Lead-Acid Battery